Step(stepper) motorlar uygun fiyatlar ile Robotistan. Aynı gün kargo, kapıda ödeme ve taksit avantajlarıyla hemen sipariş verin! This library allows you to control unipolar or bipolar stepper motors.

To use it you will need a stepper motor , and the appropriate hardware to control it. The choice of stepper motor will be different. Stepper motors are DC motors that move in discrete steps. They have multiple coils that are organized in groups called phases. By energizing each phase in sequence, the motor will rotate, one step at a time.

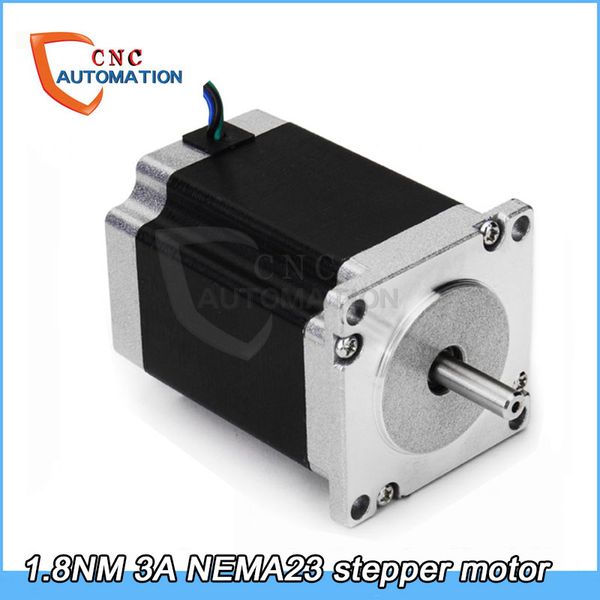

The hybrid stepper motors have the combination of the best properties of variable reluctance and permanent magnet steppers, so they are more expensive than the PM stepper motor. The hybrid type stepper motors provide better performance with respect to step resolution, torque and speed. You can find this (or similar) motors in your DVD drives, Motion camera and many more place. A hybrid stepper motor is a combination of the variable reluctance and permanent magnet type motors. The rotor of a hybrid stepper motor is axially magnetized like a permanent magnet stepper motor , and the stator is electromagnetically energized like a variable reluctance stepper motor.

The motor is attached to digital pins - of the Arduino. A potentiometer is connected to anaput 0. The higher the potentiometer value, the faster the motor speed. Unfortunately, the construction of stepper motors places a rather low-speed limitation on the motor , much lower than the speed the electronics can drive the motor.

The STM17S-3RE integrated stepper is a drive motor unit, fusing a NEMA step motor and a sophisticated 2. The digital inputs accept signal. Shop for affordable four, five, and six wire stepper motors featuring maximum torque and high reliability in a small form factor. Find more on my official website! This video gives a step-by-step explanation of variable reluctance stepper.

This NEMA 17-size pancake bipolar stepping motor from Sanyo has a 1. The fast way to control a stepper motor is just using a stepper motor driver (controller). A stepper motor divides a full rotation into a number of equal steps. The quality of every component that goes into each Lin Engineering stepper motor as well as every step of the manufacturing process is tightly scrutinized and managed to the highest standards. We follow lean manufacturing practices and even developed our own 4. Sigma Way quality assurance system.

While there is little difference between the output torque of a 2-phase stepper motor and a 5-phase stepper motor the 5-phase motor does have more useable torque. This is primarily due to the amount of torque ripple both motors produce. Every revolution of the stepper motor is divided into a discrete number of steps, in many cases 2steps, and the motor must be sent a separate pulse for each step.

Our stepper motor drivers offer adjustable current control and multiple step resolutions, and they feature built-in translators that allow a stepper motor to be controlled with simple step and direction inputs. Piece Piece (Min Order) YRS. Guangzhou Ruibao Electrical Co. Dual Y axis interface, can drive 2A phase wire stepper motor. Fit for DIY desktop laser engraver,dis.

Typical stepper motors consist of a rotating permanent magnet (rotor) surrounded by electromagnets (stator). Leave this in place when using a stepper motor. Connect to PWM output for DC motor speed control.

It is also known as Stepping Motor. The number of pulses fed into the controller circuit determines the angular rotation of the motor. Unlike a brushless DC motor , which rotates continuously when a fixed DC voltage is applied to it, a step motor rotates in discrete step angles. The center shaft has a series of magnets mounted on it, and the coils surrounding the shaft are alternately given current or not, creating magnetic fields which repulse or attract the magnets on the shaft, causing the motor to rotate.

ST’s portfolio of STSPIN stepper motor drivers spans from relatively simple ICs with current control and phase generation to more complex solutions that combine in a single chip all that is needed to autonomously drive a stepper motor using high-level motion commands coming from the motor or motion control system host – a microcontroller, DSP or FPGA. Stepper Motor is a motor controlled by a series of electromagnetic coils. The stepper motor is easy to position and moves in steps based on pulses supplied to the stator windings. Unlike the unipolar stepper motor , the bipolar stepper motor has two leads per phase, neither of which are common.

Static friction effects do happen with a H-bridge with certain drive topologies, however this can be reduced with dithering the stepper motor signal at a higher frequency. This is a brief introduction on how a stepper motor may. This stepper motor was a unipolar stepper motor which could be configured as a bipolar.

This design used stepper motors, one for each axis, and a DC motor for its extruder. Later many people upgraded their extruders to increase their control of the extruder. This 4-wire bipolar stepper has 1. The circuit Diagram for the arduino stepper motor control project is shown above. To energise the four coils of the stepper motor we are using the digital pins and 11. Stepper vs Servo The basic difference between a traditional stepper and a servo-based system is the type of motor and how it is controlled.

I used these stepper motors to drive a 3-axis automated camera track using an Arduino Uno controller and motor hat. Since the motor hat could directly control only two motors (without the provided driver boards), I used the Arduino analog pins and the provided driver board to control the third.

Hiç yorum yok:

Yorum Gönder

Not: Yalnızca bu blogun üyesi yorum gönderebilir.